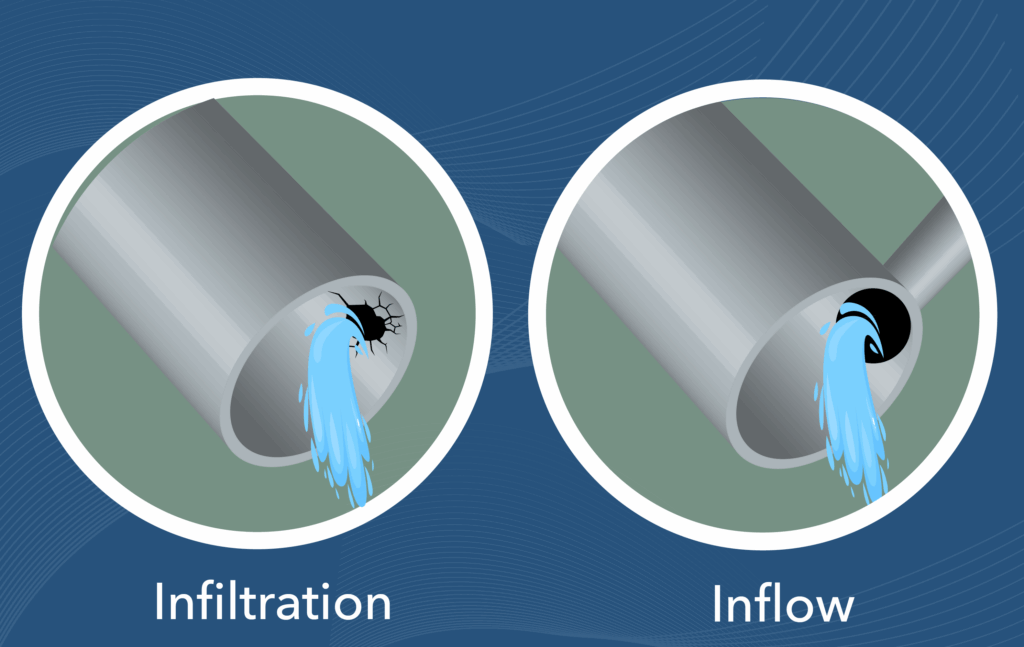

What is I&I?

I&I is inflow and infiltration of groundwater and stormwater that enter a municipal collection system and has existed since the first sewer pipes were put in the ground. I&I has several negative impacts on effective wastewater treatment including:

- increase in wastewater flow to over design capacity

- damage to the collection system

- decrease in efficiency of wastewater treatment

- decrease in wastewater detention time leading to an increase in disinfection chemicals at WWTP

- increase in overall cost to treat wastewater

- SSOs (sanitary sewer overflows)

Fixing leaks and tightening up the collection system has made a great impact on decreasing I&I. Reducing I&I, though vitally important, has one negative impact: increasing hydrogen sulfide production potential.

4 Steps to Hydrogen Sulfide Production After I&I Decrease

- Total wastewater flow decreases.

- Wastewater detention time in the force main or gravity sewer system increases.

- Naturally occurring wastewater bacteria consume all available oxygen, producing an anaerobic environment.

- Naturally occurring oxygen remains: sulfate (SO4). When bacteria pull oxygen off the sulfate molecule, an unstable sulfur ion remains, resulting in hydrogen sulfide.

Hydrogen sulfide is corrosive to wastewater collection system infrastructure, a nuisance odor, and poses a serious health and safety risk to Utility personnel and the community.

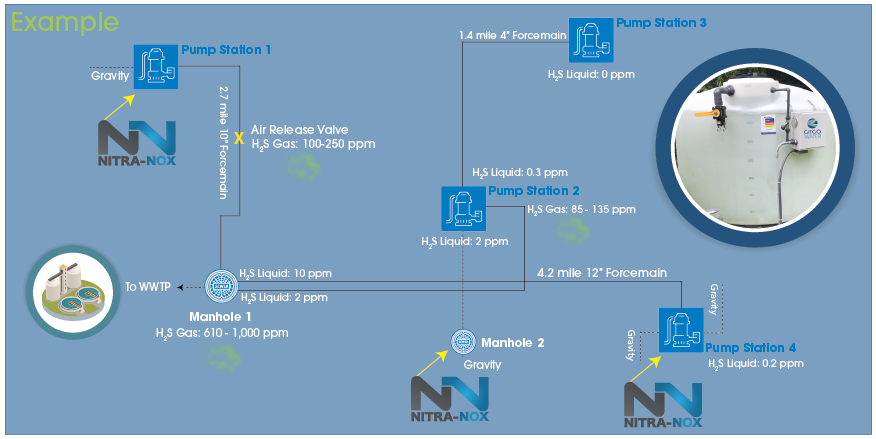

Strategic Feed for Nitra-Nox in a Municipal Collection System with Untreated Hydrogen Sulfide – Example

It’s not ‘one size fits all’ when it comes to odor control. First, the odor must be identified followed by the location of the odor, location where odor is produced, and concentration of the odor. The data presented below is hypothetical and shows the level of service and detail CITCO Water takes when evaluating a hydrogen sulfide issue and recommending an odor control trial.

The hydrogen sulfide issues (odor complaints) are at manholes receiving all flow prior to the wastewater treatment plant and the air release valve on the force main from Pump Station 1. To alleviate the odors, CITCO Water evaluated the entire collection system.

For the hydrogen sulfide issue at the manhole prior to the wastewater treatment plant, the entire system was tested for hydrogen sulfide. For the odor issue at the release valve, the hydrogen sulfide level was measured at Pump Station 1. The 0 ppm reading indicates a perfect location to feed Nitra-Nox and inhibit the production of hydrogen sulfide in the force main.

The hydrogen sulfide coming from Pump Station 1 will be inhibited by feeding at Pump Station 1. The hydrogen sulfide coming from Pump Station 4 will also have to be treated at Pump Station 4. The hydrogen sulfide coming from Pump Station 2 is further evaluated and it’s determined that the majority of the hydrogen sulfide is coming from the gravity flowing into Pump Station 2. Feeding Nitra-Nox at Manhole 2 will inhibit the hydrogen sulfide at Pump Station 2 and discharge into Manhole 1 prior to the wastewater treatment plant.

-

- Pump Station 1: 6.5 ppm

- Pump Station 2: 2 ppm

- Pump Station 4: 10 ppm

- Pump Station 3: 0 ppm